Plastic Pyrolysis

Plastic – Energy Series Article

Conversation With Chat GPT4o 27 May 2024

Articles Series: Energy

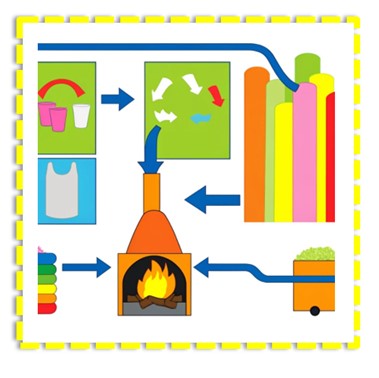

Plastic Waste Collection Artwork

F McCullough Copyright 2024 ©

Introduction To Plastic Pyrolysis

What Is Plastic Pyrolysis?

Plastic pyrolysis is a thermochemical process that converts plastic waste into valuable products such as oil, gas, and char by heating the plastic in the absence of oxygen. The absence of oxygen is crucial because it prevents combustion, allowing the plastic to decompose into smaller molecular fragments through thermal degradation.

Thermochemical Process: This term refers to the combined application of heat (thermal) and chemical reactions to break down materials. In the context of pyrolysis, it involves heating plastic to high temperatures, typically between 300°C and 700°C, in a controlled environment.

Thermal Degradation: This is the breakdown of materials caused by high temperatures. In pyrolysis, thermal degradation of plastic results in the breaking of long polymer chains into shorter hydrocarbon molecules, which are then collected as different products.

Absence of Oxygen: Pyrolysis occurs in an environment devoid of oxygen to prevent burning. If oxygen were present, the plastic would combust, resulting in the release of energy as heat and producing mainly carbon dioxide and water, rather than useful by-products.

Key Aspects Of Plastic Pyrolysis

Pyrolysis Oil: One of the main products of plastic pyrolysis is a liquid fuel known as pyrolysis oil, or bio-oil. This oil could be further refined and used as a substitute for conventional fuels.

Pyrolysis Gas: Another product is syngas, a mixture of gases primarily consisting of hydrogen, methane, carbon monoxide, and carbon dioxide. Syngas could be used to generate electricity or as a chemical feedstock.

Char: The solid residue left after pyrolysis is char, which is a carbon-rich material that could be used as a fuel or in various industrial applications.

Types Of Pyrolysis

Slow Pyrolysis: This process involves heating the plastic slowly, allowing for greater production of char and syngas. It is typically used for waste management and biochar production.

Fast Pyrolysis: In fast pyrolysis, the plastic is rapidly heated to high temperatures, maximising the yield of liquid products (pyrolysis oil). This method is often favoured for producing bio-oil.

Flash Pyrolysis: An even more rapid form of pyrolysis, flash pyrolysis involves extremely high heating rates, resulting in a high yield of liquid and gaseous products.

Benefits Of Plastic Pyrolysis

Waste Reduction: Plastic pyrolysis provides an effective means of reducing plastic waste, which is a significant environmental problem. By converting waste into useful products, it helps mitigate the issue of plastic pollution.

Energy Recovery: The process recovers energy from plastic waste, producing fuels that could be used in various applications, thereby contributing to energy sustainability.

Economic Value: The by-products of pyrolysis, especially the liquid fuel, have significant economic value, providing an incentive for the adoption of this technology.

Challenges And Considerations

Feedstock Variability: Different types of plastics yield different products, and the variability in plastic waste feedstock could affect the efficiency and consistency of the pyrolysis process.

Technology and Infrastructure: The successful implementation of plastic pyrolysis requires advanced technology and infrastructure, which could be a barrier for widespread adoption, especially in developing regions.

Environmental Impact: While pyrolysis is a more sustainable option compared to landfilling or incineration, it still produces emissions and requires careful management to minimise environmental impact.

Summary

Plastic pyrolysis represents a promising solution for managing plastic waste by converting it into valuable resources. Through understanding its mechanisms, benefits, and challenges, it becomes clear how this technology could contribute to a more sustainable future.

Key Takeaway

Plastic pyrolysis is a thermochemical process that transforms plastic waste into useful products, addressing both environmental and economic concerns.

Thought Of The Topic

Transforming plastic waste into valuable resources,

plastic pyrolysis turns today's waste into tomorrow's wealth. How could we

innovate further to enhance this transformation?

How Does Plastic Pyrolysis Differ From Other Methods Of Plastic Waste Management?

Plastic pyrolysis stands out from other plastic waste management methods due to its unique process and the range of valuable products it generates. Here, we compare plastic pyrolysis with several conventional methods: recycling, incineration, and landfilling.

Recycling

Mechanical Recycling: This method involves physically processing plastic waste to create new plastic products. It typically includes steps like sorting, cleaning, shredding, and melting the plastic.

Comparison With Pyrolysis:

Process: Mechanical recycling relies on reprocessing the physical form of plastics, whereas pyrolysis chemically decomposes plastic into simpler compounds.

Feedstock Limitation: Mechanical recycling is limited by contamination and the types of plastics it could process, often requiring plastics to be clean and of certain grades. Pyrolysis could handle mixed and contaminated plastics more effectively.

Product Range: Mechanical recycling produces new plastic materials, which might degrade in quality with each cycle. Pyrolysis generates fuels and chemicals, offering a broader range of end products.

Incineration

Incineration: This method involves burning plastic waste at high temperatures, converting it into energy, heat, and ash. It reduces the volume of waste significantly and recovers energy.

Comparison With Pyrolysis:

Process: Incineration combusts plastics in the presence of oxygen, producing heat and often releasing harmful emissions. Pyrolysis, in contrast, operates in an oxygen-free environment, thus minimising harmful emissions.

Energy Recovery: While both methods recover energy, incineration does so by generating heat and electricity directly. Pyrolysis converts plastics into fuels that could be used later, offering more flexibility in energy recovery.

Environmental Impact: Incineration could release pollutants like dioxins and furans, necessitating stringent emission controls. Pyrolysis, when well-managed, produces fewer hazardous emissions and by-products.

Landfilling

Landfilling: This is the most common method for disposing of plastic waste, where waste is buried in the ground. It is a simple and cost-effective method however has significant environmental drawbacks.

Comparison With Pyrolysis:

Environmental Impact: Landfilling contributes to long-term environmental issues such as soil and water contamination and greenhouse gas emissions from decomposing waste. Pyrolysis converts plastic waste into useful products, reducing the amount of waste destined for landfills.

Resource Recovery: Landfilling does not recover any resources from plastic waste. Pyrolysis, on the other hand, transforms waste into valuable materials like oil, gas, and char.

Space Requirement: Landfills require large areas of land, which could be problematic as waste generation increases. Pyrolysis plants, while needing infrastructure, do not demand the vast land space required by landfills.

Advanced Chemical Recycling

Advanced Chemical Recycling: This includes various chemical processes like depolymerisation and solvolysis that break down plastics into their monomers or other basic chemicals, which could then be used to make new plastics or other materials.

Comparison With Pyrolysis:

Process: Both advanced chemical recycling and pyrolysis involve breaking down plastics at a molecular level. However, chemical recycling often focuses on specific polymers and aims to produce high-purity monomers, while pyrolysis could handle mixed plastics and produces a range of hydrocarbon products.

Flexibility: Pyrolysis is typically more flexible in terms of the types of plastics it could process compared to many chemical recycling methods, which may require more homogeneous feedstock.

Output: Advanced chemical recycling outputs monomers and chemicals suitable for creating new, high-quality plastics. Pyrolysis produces fuels and industrial chemicals that have different uses.

Composting And Biodegradation

Composting and Biodegradation: These methods are applicable to biodegradable plastics, involving biological processes to break down plastic waste into natural substances like water, carbon dioxide, and compost.

Comparison With Pyrolysis:

Applicability: Composting is limited to biodegradable plastics, whereas pyrolysis could process a wide variety of non-biodegradable plastics.

Degradation Time: Composting could take a long time and is affected by environmental conditions. Pyrolysis is a faster process that quickly converts waste into usable products.

By-Products: Composting results in compost or humus, which is beneficial for soil health. Pyrolysis produces fuels and other industrial chemicals, addressing different needs and markets.

Summary

Plastic pyrolysis differentiates itself through its ability to convert a broad range of plastic waste into valuable products such as oil, gas, and char. It offers significant environmental benefits by reducing landfill use and harmful emissions compared to incineration. Furthermore, it recovers more diverse and economically valuable resources compared to traditional recycling and composting methods.

Key Takeaway

Plastic pyrolysis is distinct in converting a wide range of plastics into valuable products, addressing limitations of other waste management methods while providing environmental and economic benefits.

Thought Of The Topic

In the quest to combat plastic pollution,

understanding the unique benefits of pyrolysis over traditional recycling and

disposal methods could unlock new pathways to sustainability.

Key Chemical Processes In Plastic Pyrolysis

Plastic pyrolysis involves several critical chemical processes that collectively break down plastic polymers into smaller, valuable molecules. These processes occur in a high-temperature, oxygen-free environment and include thermal cracking, depolymerisation, isomerisation, and aromatisation.

Thermal Cracking

Thermal Cracking: Also known as pyrolytic cracking, this is the primary process in plastic pyrolysis. It involves the breaking of long polymer chains into smaller hydrocarbon molecules. This occurs when plastics are heated to temperatures typically between 300°C and 700°C.

Mechanism: During thermal cracking, the energy from the heat causes the carbon-carbon bonds in the polymer chains to break. This results in the formation of shorter chains, which could be gases, liquids, or waxes, depending on the specific conditions and types of plastics used.

Depolymerisation

Depolymerisation: This process involves reversing the polymerisation reaction that originally formed the plastic. It breaks the polymer chains back into their monomer units or smaller molecules.

Mechanism: Depolymerisation is influenced by temperature and catalysts, if used. The process aims to achieve maximum yield of monomers or other small molecules that could be easily separated and purified. For instance, polystyrene could depolymerise back into styrene monomer.

Isomerization

Isomerization: This process involves the rearrangement of atoms within molecules to form isomers, which are molecules with the same molecular formula with different structures.

Mechanism: During pyrolysis, some of the hydrocarbon fragments produced from thermal cracking could undergo isomerisation. This rearrangement could influence the properties and usability of the resulting products, particularly in enhancing the quality of liquid fuels.

Aromatization

Aromatization: This is the formation of aromatic compounds, which are stable ring-like structures, from aliphatic hydrocarbons (straight or branched chains).

Mechanism: In the high-temperature environment of pyrolysis, some hydrocarbons could cyclise to form aromatic rings. Aromatic compounds are valuable in the chemical industry for producing solvents, dyes, and other materials.

Gasification Reactions

Gasification Reactions: In pyrolysis, some of the hydrocarbon fragments could further react to form gases such as hydrogen, methane, carbon monoxide, and carbon dioxide.

Mechanism: These reactions are influenced by the temperature and the presence of catalysts. The produced gases, collectively known as syngas, could be used for energy generation or as feedstock for further chemical synthesis.

Dehydrogenation

Dehydrogenation: This process involves the removal of hydrogen atoms from hydrocarbons, leading to the formation of unsaturated compounds.

Mechanism: Dehydrogenation occurs under high temperatures and is essential for the formation of double bonds in hydrocarbon chains, which could then undergo further transformations such as aromatisation.

Secondary Reactions

Secondary Reactions: These are additional reactions that occur as primary pyrolysis products further react with each other. They could lead to the formation of more stable products like char or additional gases.

Mechanism: Secondary reactions are dependent on the residence time and temperature within the pyrolysis reactor. Longer residence times and higher temperatures generally promote more extensive secondary reactions, influencing the final composition of pyrolysis products.

Catalytic Pyrolysis

Catalytic Pyrolysis: This is a variation of standard pyrolysis where catalysts are used to lower the reaction temperatures and alter the reaction pathways, enhancing the yield and quality of desired products.

Mechanism: Catalysts, such as zeolites, are added to the pyrolysis process to facilitate specific chemical reactions. They could improve the efficiency of cracking, isomerisation, and aromatisation, resulting in higher quality fuels and chemicals.

Summary

The key chemical processes in plastic pyrolysis—thermal cracking, depolymerisation, isomerisation, aromatisation, gasification reactions, dehydrogenation, secondary reactions, and catalytic pyrolysis—work together to convert plastic waste into valuable products. These processes operate under high temperatures and in the absence of oxygen, making pyrolysis a versatile and efficient method for plastic waste management.

Key Takeaway

Plastic pyrolysis involves thermal cracking, depolymerisation, isomerisation, aromatisation, and more, transforming plastic waste into valuable products through high-temperature chemical reactions.

Thought Of The Topic

The journey from plastic waste to valuable products

is paved by complex chemical reactions. What innovations could we introduce to

make these processes more efficient and environmentally friendly

Types Of Plastics Suitable For Pyrolysis

Plastic pyrolysis is a versatile process capable of handling a wide variety of plastic types. Each type of plastic has unique characteristics that influence its behaviour during pyrolysis and the nature of the resultant products. The primary categories of plastics that could be processed through pyrolysis include polyolefins, polystyrene, polyvinyl chloride, and mixed plastic waste.

Polyolefins

Polyethylene (PE): This is one of the most common plastics, used in products like plastic bags, bottles, and films. Polyethylene could be effectively pyrolysed to produce a high yield of liquid hydrocarbons. There are two main types:

High-Density Polyethylene (HDPE): Found in rigid containers and pipes.

Low-Density Polyethylene (LDPE): Used in plastic films and flexible packaging.

Polypropylene (PP): Widely used in packaging, textiles, and automotive components. Polypropylene undergoes pyrolysis to yield a significant amount of valuable liquid fuel and waxes.

Polystyrene

Polystyrene (PS): Commonly used in disposable cutlery, CD cases, and foam packaging materials. During pyrolysis, polystyrene primarily breaks down into its monomer, styrene, which could be recovered and reused to produce new polystyrene products.

Polyvinyl Chloride

Polyvinyl Chloride (PVC): Used in construction materials, pipes, and electrical cable insulation. Pyrolysis of PVC is more challenging due to the release of hydrochloric acid (HCl) during the process. Special pre-treatment and careful control of reaction conditions are required to manage the corrosive by-products.

Mixed Plastic Waste

Mixed Plastics: Real-world plastic waste is often a heterogeneous mix of various plastic types. Pyrolysis could handle mixed plastics, although the efficiency and product distribution could vary based on the specific mix. Techniques such as co-pyrolysis, where plastics are processed together with other materials like biomass, could enhance the process and improve the quality of the output products.

Less Commonly Processed Plastics

Polyethylene Terephthalate (PET): Found in beverage bottles and food packaging. While PET could be pyrolysed, it is less common due to the availability of efficient recycling methods that convert PET back into its monomers or into new PET products.

Polycarbonate (PC): Used in eyewear lenses, electronics, and medical devices. Pyrolysis of polycarbonate is less prevalent however is possible, typically requiring specific conditions to handle its distinct thermal degradation pathway.

Acrylonitrile Butadiene Styrene (ABS): Found in household and consumer electronics, automotive trim, and LEGO bricks. ABS could be pyrolysed, although it may require more precise control of the process to manage the complex mixture of products formed.

Special Considerations

Contaminated Plastics: Plastics contaminated with organic materials, metals, or other substances could also be processed through pyrolysis, though pre-treatment may be necessary to remove or mitigate the impact of contaminants on the pyrolysis process and product quality.

Summary

Plastic pyrolysis is capable of processing a broad spectrum of plastics, including common types like polyethylene, polypropylene, polystyrene, and mixed plastic waste. While more challenging plastics like PVC and PET could also be processed, they may require specific conditions or pre-treatment. The ability to handle diverse plastic waste streams makes pyrolysis a flexible and promising method for plastic waste management.

Key Takeaway

Plastic pyrolysis could process diverse plastics, including polyolefins, polystyrene, PVC, and mixed waste, making it a versatile solution for plastic waste management.

Thought Of The Topic

Unlocking the full potential of pyrolysis involves

identifying and utilising all suitable plastic types. How could we improve

sorting and feedstock preparation to Optimise efficiency?

Temperatures And Conditions For Effective Pyrolysis

Effective plastic pyrolysis relies on specific temperatures and conditions to ensure the optimal breakdown of plastic waste into valuable products. The key parameters include temperature ranges, heating rates, residence time, reactor type, and the presence of catalysts.

Temperature Ranges

Optimal Temperature: Plastic pyrolysis typically occurs within a temperature range of 300°C to 700°C. The exact temperature depends on the type of plastic being processed and the desired end products. For instance:

Low to Medium Temperatures (300°C - 500°C): At these temperatures, the process tends to produce higher yields of liquid products (pyrolysis oil). Polyethylene and polypropylene, for instance, are effectively pyrolysed in this range, yielding significant amounts of liquid hydrocarbons.

High Temperatures (500°C - 700°C): Higher temperatures favour the production of gaseous products. Polystyrene, for example, may require higher temperatures to break down efficiently into styrene monomers and other gases.

Heating Rates

Heating Rate: The rate at which the plastic is heated influences the efficiency and type of products obtained from pyrolysis. There are two primary modes:

Slow Heating: Involves gradually increasing the temperature. This method allows for a more controlled breakdown of plastic, often resulting in higher char yields and more stable liquid products.

Fast Heating: Rapidly increases the temperature, leading to a quick thermal decomposition of plastics. Fast pyrolysis is generally preferred for maximising the yield of liquid fuels and gases, as it minimises the formation of char.

Residence Time

Residence Time: This refers to the duration that the plastic material remains in the pyrolysis reactor at the target temperature. The residence time affects the degree of decomposition and the balance between solid, liquid, and gaseous products.

Short Residence Time: Favours the production of gaseous and liquid products. This is typical in fast pyrolysis processes where plastics are quickly decomposed and removed from the reactor.

Long Residence Time: Leads to more extensive secondary reactions, which could increase the yield of char and more stable liquids. Slow pyrolysis processes usually involve longer residence times.

Reactor Type

Reactor Type: The design and type of pyrolysis reactor play a crucial role in the process's efficiency and output quality. Common types include:

Batch Reactors: Suitable for small-scale operations, batch reactors process a fixed amount of plastic per cycle, allowing for precise control over the conditions.

Continuous Reactors: Used in large-scale operations, these reactors process plastic continuously, enhancing throughput and operational efficiency. Types of continuous reactors include rotary kilns, fluidised bed reactors, and auger reactors.

Inert Atmosphere

Inert Atmosphere: Pyrolysis must occur in an oxygen-free environment to prevent combustion. An inert gas, such as nitrogen or argon, is often used to purge oxygen from the reactor and maintain the necessary conditions.

Nitrogen: Commonly used due to its availability and effectiveness in creating an inert atmosphere.

Argon: Sometimes used for its superior inert properties, though it is more expensive than nitrogen.

Catalysts

Catalysts: Catalytic pyrolysis involves the use of catalysts to lower the required reaction temperature, enhance product selectivity, and improve the quality of the output.

Zeolites: Widely used catalysts that could improve the yield and quality of liquid hydrocarbons.

Metal Oxides: These could enhance the breakdown of complex plastic polymers and increase the production of desirable products like fuel-grade hydrocarbons.

Pressure Conditions

Pressure Conditions: Although pyrolysis typically occurs at atmospheric pressure, variations in pressure could influence the process and the nature of the products.

Atmospheric Pressure: Standard condition for most pyrolysis processes, providing a balance between operational simplicity and efficiency.

Vacuum Pyrolysis: Lowering the pressure could reduce the boiling points of the products, aiding in the extraction of high-purity liquids.

High-Pressure Pyrolysis: Increasing pressure could sometimes enhance the yield of certain products, though it requires more robust reactor designs and safety measures.

Summary

Effective pyrolysis requires precise control of temperature, heating rates, residence time, reactor design, inert atmosphere, catalysts, and pressure conditions. These factors collectively determine the efficiency, product distribution, and quality of the pyrolysis process.

Key Takeaway

Effective pyrolysis needs temperatures of 300°C to 700°C, precise heating rates, controlled residence time, suitable reactors, an inert atmosphere, catalysts, and appropriate pressure conditions.

Thought Of The Topic

Precision in temperature and conditions defines the

success of pyrolysis. What advancements could we make to achieve optimal and

consistent operating parameters?

Impact Of Plastic Composition On Pyrolysis Process

The composition of plastic significantly influences the efficiency and outcomes of the pyrolysis process. Various factors, including polymer type, additives, contamination, and molecular structure, determine how plastics decompose and what products are generated.

Polymer Type

Polyolefins: Plastics like polyethylene (PE) and polypropylene (PP) are hydrocarbons composed solely of carbon and hydrogen atoms. Their simple structure makes them highly suitable for pyrolysis, often yielding a high proportion of liquid hydrocarbons and waxes. These plastics typically decompose into shorter chains of alkanes and alkenes, which could be refined into fuels and other valuable chemicals.

Polystyrene (PS): This polymer consists of long chains with phenyl groups attached, which decompose into styrene monomers and other aromatic compounds during pyrolysis. The aromatic nature of polystyrene results in a distinct product profile, with a high yield of valuable styrene that could be repolymerised into new plastic products.

Polyvinyl Chloride (PVC): PVC contains chlorine atoms within its polymer structure. During pyrolysis, it releases hydrochloric acid (HCl), which is corrosive and poses environmental hazards. Special handling, such as pre-treatment or the use of neutralising agents, is necessary to manage these by-products. The presence of chlorine also affects the composition of the pyrolysis products, often necessitating additional purification steps.

Polyethylene Terephthalate (PET): PET is a polyester that includes ester linkages in its backbone. Its pyrolysis could produce terephthalic acid, ethylene glycol, and other compounds. However, the efficiency is often lower compared to polyolefins, and specialised conditions are needed to optimise the breakdown and recovery of valuable products.

Additives

Plasticizers and Stabilizers: Many plastics contain additives to enhance their properties, such as flexibility, durability, and UV resistance. These additives could impact the pyrolysis process by altering the thermal degradation pathways and potentially producing additional by-products. For instance, plasticisers in flexible PVC could volatilise at lower temperatures, affecting the overall process dynamics and product composition.

Fillers and Reinforcements: Some plastics include inorganic fillers (e.g., calcium carbonate, glass fibres) to improve mechanical strength and reduce costs. These additives do not decompose during pyrolysis and remain as solid residues (char), which could influence the yield and quality of liquid and gaseous products.

Flame Retardants: Plastics used in applications requiring fire resistance often contain flame retardants. These chemicals could release halogens or phosphorous compounds during pyrolysis, complicating the process and necessitating advanced gas cleaning systems to manage potentially toxic emissions.

Contamination

Organic Contaminants: Plastics contaminated with food residues, oils, or other organic substances could alter the pyrolysis process. These contaminants may decompose alongside the plastic, producing additional gases and potentially fouling the pyrolysis reactor. Pre-treatment steps, such as washing or thermal desorption, are often needed to reduce contamination levels.

Inorganic Contaminants: Metals, dirt, and other inorganic materials could also affect pyrolysis. Metals might catalyse unwanted reactions, while dirt and other solids could increase char production and reduce the efficiency of liquid fuel generation. Effective sorting and cleaning processes are crucial to minimise these impacts.

Molecular Structure

Crystallinity: The degree of crystallinity in a plastic influences its thermal stability and decomposition behaviour. Amorphous plastics (e.g., atactic polypropylene) typically decompose at lower temperatures and more uniformly compared to highly crystalline plastics (e.g., isotactic polypropylene), which require higher temperatures for complete breakdown.

Molecular Weight: Plastics with higher molecular weights tend to decompose into larger fragments initially, which may then require further cracking to yield smaller, useful products. Lower molecular weight plastics often produce smaller fragments directly, making the process more efficient.

Mixed Plastic Waste

Heterogeneity: Mixed plastic waste presents challenges due to the varying decomposition characteristics of different plastics. The presence of multiple types of plastics could lead to complex reaction pathways, influencing the overall yield and quality of the pyrolysis products. Co-pyrolysis strategies, where different plastics are processed together, could be optimised to enhance synergies between the materials and improve product outcomes.

Summary

The composition of plastic—encompassing polymer type, additives, contamination, and molecular structure—affects the pyrolysis process's efficiency and product distribution. Understanding these influences is essential for optimising the pyrolysis of diverse plastic waste streams and achieving desirable outputs.

Key Takeaway

Plastic composition, including polymer type, additives, contamination, and molecular structure, crucially impacts pyrolysis efficiency and product outcomes, necessitating tailored process optimisation.

Thought Of The Topic

The composition of plastic waste directly impacts

the efficiency and outputs of pyrolysis. How could we tailor the process to

handle diverse and mixed plastic streams effectively?

Benefits Of Plastic Pyrolysis Over Traditional Recycling Methods

Plastic pyrolysis offers several advantages over conventional recycling methods, addressing many of the limitations associated with traditional approaches. These benefits include handling a broader range of plastic types, reducing landfill waste, generating valuable products, and enhancing economic and environmental sustainability.

Broader Range Of Plastic Types

Versatility: Traditional recycling methods are often limited to specific types of plastics, such as PET and HDPE, which could be mechanically recycled. Many other plastics, including mixed or contaminated waste, are not easily recyclable. Pyrolysis could process a wide variety of plastics, including complex and multi-layered materials, which are typically excluded from mechanical recycling processes.

Mixed and Contaminated Plastics: Pyrolysis could handle plastics that are mixed or contaminated with food residues, dirt, or other substances. While pre-treatment may be necessary, pyrolysis is more forgiving of contaminants compared to mechanical recycling, which requires clean, sorted plastic streams.

Reduction Of Landfill Waste

Waste Minimisation: By converting non-recyclable plastics into valuable products, pyrolysis significantly reduces the volume of plastic waste that ends up in landfills. This helps mitigate the environmental impact associated with landfill usage, such as soil and water contamination and the generation of methane, a potent greenhouse gas.

Circular Economy Contribution: Pyrolysis supports a circular economy by transforming waste plastics into useful resources, thereby closing the loop on plastic use and reducing the need for virgin plastic production.

Generation Of Valuable Products

High-Value Outputs: Pyrolysis produces a range of valuable products, including liquid fuels, waxes, and chemicals. These outputs could be used as feedstocks for the petrochemical industry, reducing reliance on fossil fuels and providing an alternative source of raw materials.

Energy Recovery: The gases produced during pyrolysis, such as hydrogen and methane, could be utilised for energy generation, providing a renewable energy source and improving the overall energy balance of the process.

Economic Benefits

Market Demand: The products of pyrolysis, particularly liquid fuels and chemicals, have a strong market demand. This could create economic incentives for waste management companies to adopt pyrolysis technologies, driving investment and innovation in the sector.

Job Creation: The development and operation of pyrolysis plants could generate employment opportunities in areas such as plant construction, operation, maintenance, and research.

Environmental Sustainability

Reduced Greenhouse Gas Emissions: Pyrolysis offers a lower-carbon alternative to incineration, which releases significant amounts of CO2 and other pollutants. By converting plastics into reusable hydrocarbons, pyrolysis could reduce overall greenhouse gas emissions compared to landfilling and incineration.

Lower Pollution Levels: Unlike mechanical recycling, which could degrade the quality of plastics over multiple recycling cycles, pyrolysis breaks down plastics into their basic chemical components, maintaining their quality. This helps avoid the accumulation of microplastics in the environment.

Energy Efficiency

Efficient Conversion: Pyrolysis could convert a high percentage of plastic feedstock into useful products. With optimised processes, the energy input required could be balanced by the energy content of the outputs, making pyrolysis an energy-efficient solution.

Catalytic Improvements: The use of catalysts in pyrolysis could enhance the efficiency and selectivity of the process, lowering the required temperatures and improving the quality and yield of the products.

Flexibility And Scalability

Adaptability: Pyrolysis technology could be adapted to various scales, from small, localised units to large, industrial-scale plants. This flexibility allows it to be implemented in diverse settings, addressing local waste management needs effectively.

Technological Advancements: Ongoing research and development are continuously improving pyrolysis technologies, making them more efficient, cost-effective, and environmentally friendly. Innovations such as advanced reactors and better catalysts contribute to the evolving capabilities of pyrolysis.

Summary

Plastic pyrolysis offers significant benefits over traditional recycling methods by handling a broader range of plastics, reducing landfill waste, generating valuable products, and contributing to economic and environmental sustainability. Its versatility, efficiency, and adaptability make it a promising solution for addressing the global plastic waste crisis.

Key Takeaway

Plastic pyrolysis surpasses traditional recycling by processing diverse plastics, minimising landfill waste, generating valuable products, and enhancing economic and environmental sustainability.

Thought Of The Topic

Plastic pyrolysis offers unique advantages over conventional recycling. How could we leverage these benefits to create more sustainable and circular waste management systems?

Environmental Impacts Of Plastic Pyrolysis

Plastic pyrolysis, while offering numerous advantages over traditional recycling methods, also has specific environmental impacts. These impacts could be both positive and negative, depending on the implementation and management of the pyrolysis process. Understanding these impacts is crucial for optimizing the technology to ensure its environmental sustainability.

Positive Environmental Impacts

Reduction in Landfill Waste

Waste Diversion: Pyrolysis diverts plastic waste from landfills, significantly reducing the volume of waste that would otherwise contribute to soil and groundwater contamination. Landfills are known for leaching harmful chemicals into the environment, and by diverting plastic waste, pyrolysis helps mitigate these issues.

Decreased Methane Emissions: Landfills are major sources of methane, a potent greenhouse gas. By reducing the amount of plastic waste sent to landfills, pyrolysis helps lower methane emissions, contributing to climate change mitigation efforts.

Lower Incineration Rates

Avoidance of Incineration: Incineration of plastic waste releases substantial amounts of CO2 and other pollutants into the atmosphere. Pyrolysis provides an alternative by converting plastics into useful products without the harmful emissions associated with burning.

Reduced Air Pollution: Unlike incineration, which could release toxic substances such as dioxins and furans, pyrolysis, when properly managed, produces fewer airborne pollutants, resulting in improved air quality.

Resource Recovery

Circular Economy Contribution: Pyrolysis transforms waste plastics into valuable hydrocarbons, which could be used to produce new plastic products, fuels, and chemicals. This promotes a circular economy, reducing the need for virgin materials and the environmental impact of extracting and processing new resources.

Energy Recovery: The process generates energy-rich gases that could be used to produce electricity or heat, reducing reliance on fossil fuels and lowering the carbon footprint of energy production.

Negative Environmental Impacts

Emission Of Pollutants

Volatile Organic Compounds (VOCs): During pyrolysis, some volatile organic compounds may be released. These VOCs could contribute to air pollution and have health impacts if not properly managed with adequate emission control systems.

Incomplete Combustion By-products: If the process is not optimally controlled, incomplete combustion could result in the release of by-products such as carbon monoxide (CO) and particulate matter, which are harmful to both health and the environment.

Handling Of Hazardous By-products

Chlorinated Compounds: Pyrolysis of plastics containing chlorine, such as PVC, could produce hydrochloric acid and other chlorinated compounds. These by-products are corrosive and toxic, necessitating effective treatment and neutralization systems to prevent environmental contamination.

Heavy Metals and Additives: Some plastics contain heavy metals and other additives that could become concentrated in the char or ash produced by pyrolysis. Proper disposal or treatment of these residues is essential to prevent soil and water pollution.

Energy Consumption And Carbon Footprint

Energy Requirements: Pyrolysis is an energy-intensive process, requiring significant heat to break down plastic polymers. The energy input could contribute to the overall carbon footprint if sourced from fossil fuels. Using renewable energy sources could mitigate this impact.

Carbon Emissions: Although pyrolysis produces fewer direct emissions compared to incineration, it still releases some CO2. Ensuring that the process is energy-efficient and utilises emission control technologies could help minimise its carbon footprint.

Waste Management And Residuals

Solid Residues: The process generates solid residues, including char and ash, which must be managed properly. These residues could contain contaminants and require safe disposal or potential utilisation in applications such as construction materials to prevent environmental harm.

Water Usage and Contamination: Some pyrolysis systems use water for cooling or quenching products, leading to potential water contamination. Implementing water recycling and treatment systems could mitigate this impact and ensure sustainable water usage.

Summary

The environmental impacts of plastic pyrolysis encompass both positive and negative aspects. Positively, it reduces landfill waste, lowers incineration rates, promotes resource recovery, and contributes to a circular economy. Negatively, it could emit pollutants, generate hazardous by-products, consume significant energy, and produce residual waste. Proper management and optimisation of the process are crucial to enhancing its environmental benefits and mitigating adverse effects.

Key Takeaway

Plastic pyrolysis reduces landfill waste and promotes resource recovery and could emit pollutants and consume energy, necessitating proper management to enhance environmental benefits.

Thought Of The Topic

While plastic pyrolysis reduces waste and recovers

resources, understanding and mitigating its environmental impacts is crucial.

How could we refine the process to minimise its ecological footprint?

Health Risks Associated With Plastic Pyrolysis

While plastic pyrolysis presents significant environmental and economic advantages, it also poses potential health risks. These risks stem from the emissions, by-products, and operational hazards associated with the process. Addressing these health concerns is critical for ensuring safe and sustainable implementation.

Emission Of Harmful Gases

Volatile Organic Compounds (VOCs)

Nature of VOCs: Volatile organic compounds are a group of organic chemicals that could easily become vapours or gases. During pyrolysis, certain VOCs could be released from the breakdown of plastic materials.

Health Impacts: Exposure to VOCs could lead to a range of health issues, including respiratory problems, headaches, dizziness, and in severe cases, damage to the liver, kidney, and central nervous system. Long-term exposure to certain VOCs has been linked to cancer.

Incomplete Combustion By-products

Carbon Monoxide (CO)

Formation: Incomplete combustion during the pyrolysis process could produce carbon monoxide, a colourless and odourless gas that is highly toxic.

Health Impacts: CO interferes with the body’s ability to transport oxygen, leading to symptoms such as headaches, dizziness, confusion, and at high levels, it could be fatal. Ensuring complete combustion and efficient process control could mitigate CO emissions.

Polycyclic Aromatic Hydrocarbons (PAHs)

Formation: PAHs are produced during the thermal decomposition of organic materials. In pyrolysis, the breakdown of complex plastic polymers could generate these compounds.

Health Impacts: PAHs are known carcinogens and could also cause skin irritation, respiratory problems, and other health issues. Long-term exposure increases the risk of cancer.

Hazardous By-products

Chlorinated Compounds

Formation: Plastics containing chlorine, such as polyvinyl chloride (PVC), could produce chlorinated compounds like hydrochloric acid (HCl) and dioxins during pyrolysis.

Health Impacts: HCl is corrosive and could cause severe respiratory and skin irritation. Dioxins are highly toxic and could lead to reproductive and developmental problems, immune system damage, and cancer. Proper handling and neutralisation are essential to mitigate these risks.

Heavy Metals And Additives

Nature of Additives: Plastics often contain additives such as stabilisers, plasticisers, and flame retardants, which may include heavy metals like lead, cadmium, and mercury.

Health Impacts: These substances could become concentrated in the residual char or ash. Exposure to heavy metals could cause neurological damage, kidney disease, and other serious health issues. Effective waste management and treatment protocols are necessary to handle these residues safely.

Occupational Hazards

High Temperatures And Pressures

Operational Conditions: Pyrolysis requires high temperatures and, in some cases, high pressures. Workers are at risk of burns, explosions, and other thermal injuries if proper safety measures are not in place.

Health Impacts: Thermal injuries could range from minor burns to severe, life-threatening conditions. Comprehensive safety training and protective equipment are critical for preventing such accidents.

Exposure To Toxic Substances

Nature of Exposure: Workers involved in the pyrolysis process may be exposed to toxic substances through inhalation, skin contact, or accidental ingestion.

Health Impacts: Long-term exposure to toxic emissions and by-products could lead to chronic health conditions, including respiratory diseases, skin disorders, and systemic toxicity. Implementing rigorous monitoring, ventilation, and personal protective equipment (PPE) protocols could reduce these risks.

Airborne Particulate Matter

Formation: Pyrolysis could generate fine particulate matter (PM), especially if the process is not optimally controlled. These particles could be inhaled deeply into the lungs.

Health Impacts: Inhalation of PM could cause respiratory and cardiovascular diseases, including asthma, bronchitis, and heart attacks. Long-term exposure increases the risk of lung cancer. Effective filtration and emission control systems are essential to minimise particulate emissions.

Summary

While plastic pyrolysis offers numerous benefits, it also poses potential health risks, including exposure to VOCs, incomplete combustion by-products, chlorinated compounds, heavy metals, and occupational hazards. Addressing these risks through proper management, safety protocols, and emission control measures is essential for ensuring the health and safety of workers and surrounding communities.

Key Takeaway

Plastic pyrolysis poses health risks from VOCs, by-products like CO and PAHs, heavy metals, and occupational hazards. Effective management and safety measures are crucial to mitigate these risks.

Thought Of The Topic

Ensuring the health and safety of workers and

communities is paramount. What measures could we implement to mitigate

potential health risks in the pyrolysis process?

Economic Implications Of Adopting Plastic Pyrolysis On A Large Scale

The adoption of plastic pyrolysis on a large scale carries significant economic implications, encompassing job creation, market dynamics, investment requirements, operational costs, and potential revenue streams. Understanding these implications is vital for stakeholders considering the widespread implementation of this technology.

Job Creation And Employment Opportunities

Direct Employment

Plant Operations: Large-scale adoption of plastic pyrolysis would necessitate the construction and operation of numerous facilities. This creates jobs in various roles, including plant operators, maintenance personnel, and administrative staff.

Engineering and Construction: The development of pyrolysis plants requires skilled engineers, construction workers, and project managers, leading to job creation in these sectors. The demand for these professionals could stimulate local economies and provide long-term employment opportunities.

Research and Development: Advancing pyrolysis technology involves continuous research and development (R&D), fostering employment in scientific and engineering fields. Innovations in process efficiency, catalyst development, and emissions control are critical areas of focus.

Market Dynamics And Revenue Streams

Product Sales

Fuel Production: Pyrolysis converts plastic waste into valuable liquid fuels, such as diesel and gasoline, which could be sold in the energy market. This creates a new revenue stream, potentially offsetting the costs of waste management and reducing reliance on fossil fuels.

Chemical Feedstocks: The process also produces chemicals like naphtha and syngas, which could be used as feedstocks in the petrochemical industry. These products have substantial market demand, providing additional revenue opportunities.

Wax and Lubricants: Pyrolysis yields waxes and lubricating oils that could be sold for various industrial applications, further diversifying the revenue streams and enhancing economic viability.

Circular Economy Benefits

Resource Recovery: By converting waste plastics into reusable materials, pyrolysis supports a circular economy, reducing the need for virgin raw materials and lowering environmental costs associated with plastic production.

Cost Savings: Companies adopting pyrolysis could benefit from reduced waste disposal costs and potential savings on raw material procurement, improving their overall economic efficiency.

Investment Requirements And Financial Challenges

Capital Expenditure

Initial Investment: Establishing pyrolysis plants requires substantial capital investment for equipment, land acquisition, and infrastructure development. The high upfront costs could be a barrier to entry, necessitating government incentives or private financing to support large-scale adoption.

Technological Infrastructure: Advanced pyrolysis technologies, such as catalytic and microwave-assisted pyrolysis, involve higher costs and offer improved efficiency and product quality. Investing in these technologies could yield long-term economic benefits despite the initial financial outlay.

Operational Costs And Efficiency

Energy Consumption

Energy Requirements: Pyrolysis is an energy-intensive process, requiring significant heat input to break down plastic polymers. The cost of energy could impact the overall economic feasibility, particularly if sourced from non-renewable resources. Utilising renewable energy could mitigate this impact.

Maintenance and Labour: Ongoing operational costs include maintenance of equipment, labour costs, and energy expenses. Efficient plant management and optimisation of the pyrolysis process are crucial to maintaining economic viability.

Government Policies And Incentives

Regulatory Support

Subsidies and Grants: Governments could play a pivotal role by providing subsidies, grants, and tax incentives to encourage the adoption of pyrolysis technologies. These financial incentives could lower the barriers to entry and support the growth of the industry.

Regulation and Standards: Implementing clear regulations and standards for pyrolysis operations ensures environmental compliance and promotes public trust. Regulatory frameworks could drive investment and support sustainable economic growth.

Carbon Credits And Environmental Taxes

Carbon Offset: Companies investing in pyrolysis may benefit from carbon credits by reducing greenhouse gas emissions. These credits could be traded in carbon markets, providing an additional revenue stream and incentivising environmental sustainability.

Environmental Taxes: Implementing taxes on landfill usage and incineration could make pyrolysis a more economically attractive option by creating a financial disincentive for less sustainable waste management practices.

Market Competitiveness And Scale Economies

Economies of Scale

Cost Reduction: Large-scale adoption of pyrolysis could lead to economies of scale, reducing the per-unit cost of processing plastic waste. Increased production capacity and technological advancements could lower the operational costs and enhance competitiveness.

Market Penetration: As pyrolysis technology matures and becomes more widely adopted, it could capture a larger share of the waste management and recycling market. This market penetration could drive further investment and innovation, fostering a robust economic ecosystem.

Summary

The large-scale adoption of plastic pyrolysis has significant economic implications, including job creation, diverse revenue streams, high initial investment, and operational costs. Government incentives, regulatory support, and economies of scale are essential for realising the full economic potential of pyrolysis technology.

Key Takeaway

Adopting plastic pyrolysis on a large scale impacts the economy through job creation, diverse revenue streams, high investment, operational costs, and requires government incentives and regulatory support.

Thought Of The Topic

Scaling up plastic pyrolysis presents economic

opportunities and challenges. How could we balance these to foster widespread

adoption and economic sustainability?

Types Of Equipment Used In Plastic Pyrolysis

Plastic pyrolysis involves various specialised equipment designed to efficiently convert plastic waste into valuable products through thermal decomposition. Each piece of equipment plays a crucial role in ensuring the process's efficiency, safety, and environmental compliance. Here is a detailed discussion of the primary equipment used in plastic pyrolysis:

Feedstock Preparation Equipment

Shredders And Granulators

Function: Shredders and granulators are used to break down large plastic waste materials into smaller, more manageable pieces. This increases the surface area of the feedstock, facilitating more uniform and efficient pyrolysis.

Importance: Properly sized feedstock ensures consistent feeding into the pyrolysis reactor and enhances the overall efficiency of the thermal decomposition process.

Pyrolysis Reactors

Batch Reactors

Design: Batch reactors are used for small-scale operations where the plastic waste is processed in discrete batches. These reactors are simple and flexible and may have lower throughput compared to continuous systems.

Operation: The reactor is loaded with plastic waste, heated to the desired temperature, and allowed to undergo pyrolysis before being emptied and prepared for the next batch.

Continuous Reactors

Design: Continuous reactors are designed for large-scale operations, allowing for the continuous feeding of plastic waste and removal of products. These reactors offer higher efficiency and productivity.

Types:

Rotary Kilns: These reactors consist of a rotating cylindrical chamber that provides uniform heating and mixing of the feedstock. They are versatile and widely used in industrial applications.

Fluidised Bed Reactors: These reactors use a bed of inert particles, fluidised by a gas stream, to ensure efficient heat transfer and mixing. They offer excellent temperature control and could process a wide range of feedstock types.

Fixed Bed Reactors: These reactors have a stationary bed of catalyst or inert material through which the plastic feedstock passes. They are simpler in design and may have limitations in terms of feedstock flexibility and scale.

Heating Systems

Furnaces And Burners

Function: Furnaces and burners provide the necessary heat for the pyrolysis process. They could be powered by various fuels, including natural gas, electricity, or even the syngas produced during pyrolysis.

Efficiency: Advanced heating systems ensure precise temperature control, which is critical for optimising the pyrolysis process and maximising product yield.

Condensation Systems

Condensers

Function: Condensers cool down the pyrolysis vapours, converting them into liquid products such as oils and waxes. This is a crucial step in recovering valuable products from the pyrolysis process.

Types:

Air-cooled Condensers: Use air to cool and condense the vapours.

Water-cooled Condensers: Use water as a cooling medium, often more efficient and require a water supply and handling system.

Cooling Towers

Function: Cooling towers support water-cooled condensers by dissipating the heat absorbed by the cooling water, maintaining the efficiency of the condensation process.

Gas Collection And Treatment Systems

Gas Scrubbers

Function: Gas scrubbers remove impurities and contaminants from the gases produced during pyrolysis. This is essential for ensuring the safety and environmental compliance of the process.

Types:

Wet Scrubbers: Use a liquid to capture and neutralise harmful gases.

Dry Scrubbers: Use dry materials to adsorb and neutralise contaminants.

Filters

Function: Filters are used to remove particulate matter and other solid impurities from the gas stream. This ensures that the gases could be safely utilised or further processed.

Product Recovery And Storage Systems

Liquid Storage Tanks

Function: These tanks store the liquid products, such as pyrolysis oil and wax, after they have been condensed. Proper storage is essential for maintaining product quality and safety.

Design: Tanks are typically designed to handle the specific properties of the pyrolysis products, including their chemical reactivity and temperature requirements.

Gas Storage Tanks

Function: Gas storage tanks store the syngas produced during pyrolysis. This gas could be used for energy generation or as a feedstock for further chemical processing.

Auxiliary Systems

Feedstock Feeders

Function: Feedstock feeders control the rate at which plastic waste is introduced into the pyrolysis reactor. Consistent feeding is crucial for maintaining optimal reactor conditions.

Types:

Screw Feeders: Use a rotating screw mechanism to transport the feedstock.

Belt Conveyors: Use a belt to move the feedstock, suitable for continuous feeding systems.

Control Systems

Function: Control systems monitor and regulate the various parameters of the pyrolysis process, including temperature, pressure, and feed rate. Advanced control systems use sensors and automated feedback loops to optimise process conditions.

Importance: Effective control systems enhance the efficiency, safety, and reliability of the pyrolysis operation, ensuring consistent product quality and process stability.

Summary

Plastic pyrolysis requires a range of specialised equipment, including feedstock preparation tools, pyrolysis reactors, heating systems, condensation systems, gas treatment systems, and product storage facilities. Each piece of equipment plays a vital role in ensuring the efficiency, safety, and environmental compliance of the pyrolysis process.

Key Takeaway

Plastic pyrolysis equipment includes shredders, reactors, heating systems, condensers, gas scrubbers, filters, and storage tanks, each ensuring efficient, safe, and compliant operation.

Thought Of The Topic

The heart of pyrolysis lies in its equipment. How

could advancements in technology enhance the efficiency and effectiveness of

pyrolysis systems?

How A Pyrolysis Reactor Works

A pyrolysis reactor is the central component in the pyrolysis process, where plastic waste undergoes thermal decomposition to produce valuable products such as fuels, gases, and chemicals. Understanding how a pyrolysis reactor works involves examining its design, operational phases, and the chemical reactions that occur within it.

Design And Structure Of A Pyrolysis Reactor

Reactor Types

Batch Reactors

Configuration: Batch reactors process plastic waste in discrete batches. These reactors are loaded with a specific quantity of feedstock, which undergoes pyrolysis before the reactor is emptied and prepared for the next batch.

Applications: Suitable for small-scale operations or experimental setups where flexibility and control over each batch are important.

Continuous Reactors

Configuration: Continuous reactors allow for the uninterrupted feeding of plastic waste and continuous removal of pyrolysis products. This design enhances throughput and operational efficiency.

Types:

Rotary Kilns: Feature a rotating cylindrical chamber that provides uniform heating and mixing. Ideal for processing heterogeneous waste streams.

Fluidised Bed Reactors: Utilise a bed of inert particles fluidised by a gas stream, ensuring efficient heat transfer and mixing.

Fixed Bed Reactors: Have a stationary bed of catalyst or inert material through which the plastic feedstock passes.

Operational Phases

Pre-heating

Purpose: The reactor is pre-heated to the target temperature to initiate the pyrolysis process. This is typically done using external heat sources such as natural gas burners or electric heaters.

Temperature Control: Precise temperature control is crucial to ensure the desired reactions occur and to prevent incomplete pyrolysis or formation of unwanted by-products.

Feeding

Mechanism: The plastic feedstock is introduced into the reactor using feeders such as screw conveyors or belt conveyors. Continuous reactors use automated feeding systems to maintain a steady supply of material.

Importance: Consistent feeding ensures uniform thermal exposure and optimal reactor performance.

Pyrolysis

Heating: The plastic waste is heated in the absence of oxygen to prevent combustion. The temperature typically ranges from 300°C to 900°C, depending on the desired product output.

Chemical Reactions: At elevated temperatures, the long-chain polymer molecules in the plastic, break down into shorter hydrocarbon chains through thermal cracking. This results in the formation of gases, liquid oils, waxes, and char.

Heat Transfer: Efficient heat transfer is essential for uniform decomposition. Different reactor designs achieve this through various mechanisms, such as rotating chambers in rotary kilns or fluidised beds that enhance contact between the plastic and the heating medium.

Product Separation

Gaseous Products: The gaseous products, including syngas and volatile organic compounds, are collected and cooled in condensers to separate out the liquid oils and waxes.

Liquid Products: The condensed liquids are further separated into different fractions, such as pyrolysis oil and wax, using distillation or other separation techniques.

Solid Residues: The solid residue, primarily char, is collected at the end of the process. This char could be used as a fuel, a source of carbon black, or in other applications.

Chemical Reactions In The Reactor

Thermal Cracking

Mechanism: The primary reaction in pyrolysis is thermal cracking, where high temperatures break the chemical bonds in the plastic polymers. This process generates smaller hydrocarbon molecules.

Endothermic Nature: Thermal cracking is an endothermic reaction, meaning it absorbs heat. Maintaining sufficient heat input is crucial to sustain the process.

Devolatilization

Mechanism: During pyrolysis, volatile components are released from the plastic feedstock. These volatiles are then condensed into liquid products or collected as gases.

Product Composition: The composition of the volatiles depends on the type of plastic being processed and the pyrolysis conditions. Common products include alkanes, alkenes, and aromatic hydrocarbons.

Secondary Reactions

Catalytic Cracking: In some pyrolysis systems, catalysts are used to enhance the breakdown of plastic molecules. Catalysts could lower the required reaction temperature and improve the yield of desired products.

Hydrogenation: In hydrogen-rich environments, some of the cracked hydrocarbons undergo hydrogenation, forming more stable saturated compounds.

Reactor Control And Optimisation

Temperature Management

Sensors and Controls: Temperature sensors and automated control systems are used to maintain the reactor at the desired temperature. This ensures optimal reaction conditions and maximises product yield.

Heating Methods: Depending on the reactor design, different heating methods, such as direct heating (using burners) or indirect heating (using heat exchangers), are employed to achieve uniform temperature distribution.

Pressure Control

Vacuum Systems: Some pyrolysis reactors operate under reduced pressure (vacuum) to lower the pyrolysis temperature and enhance product quality. Vacuum systems are used to maintain the desired pressure conditions.

Gas Management: The non-condensable gases produced during pyrolysis are either flared off, used for energy recovery, or recycled back into the process to maintain pressure and heat balance.

Summary

A pyrolysis reactor operates through a series of carefully controlled steps, including pre-heating, feeding, thermal decomposition, and product separation. The design and operation of the reactor are crucial for optimising the pyrolysis process, ensuring efficient conversion of plastic waste into valuable products while managing temperature, pressure, and chemical reactions.

Key Takeaway

A pyrolysis reactor decomposes plastic waste by heating it in the absence of oxygen, using controlled temperature and pressure, to produce gases, oils, and solid residues.

Thought Of The Topic

Understanding the intricate workings of a pyrolysis

reactor is key to innovation. What improvements could we make to optimise

reactor design and performance?

Key Components Of A Plastic Pyrolysis Plant

A plastic pyrolysis plant comprises several essential components, each playing a specific role in the conversion of plastic waste into valuable products such as fuels, gases, and chemicals. These components work together to ensure efficient, safe, and environmentally compliant operations. Here, we will discuss the main components and their functions in detail.

Feedstock Preparation System

Shredders And Granulators

Function: Shredders and granulators are used to reduce the size of plastic waste into smaller, uniform pieces. This preprocessing step is crucial for ensuring that the plastic feedstock is adequately prepared for the pyrolysis process.

Importance: Properly sized feedstock facilitates consistent feeding into the reactor and improves the efficiency of thermal decomposition.

Feeding System

Feedstock Feeders

Types: Screw feeders, belt conveyors, and pneumatic feeders are commonly used to transport the prepared plastic waste into the pyrolysis reactor.

Role: These systems ensure a continuous and controlled supply of feedstock into the reactor, which is vital for maintaining steady-state conditions in continuous pyrolysis operations.

Pyrolysis Reactor

Batch And Continuous Reactors

Function: The reactor is where the core pyrolysis process takes place. It heats the plastic waste in an oxygen-free environment, causing it to thermally decompose into smaller hydrocarbon molecules.

Types:

Rotary Kilns: Provide uniform heating and mixing by rotating.

Fluidised Bed Reactors: Ensure efficient heat transfer and mixing through fluidisation.

Fixed Bed Reactors: Have a stationary bed for processing the feedstock.

Heating System

Furnaces And Burners

Role: Furnaces and burners provide the necessary heat for the pyrolysis reaction. They are typically powered by natural gas, electricity, or even the syngas produced during the pyrolysis process.

Efficiency: Advanced heating systems are designed to provide precise temperature control, which is critical for optimising the pyrolysis process and ensuring consistent product quality.

Condensation System

Condensers

Types: Air-cooled and water-cooled condensers are used to cool the pyrolysis vapours and condense them into liquid products such as oils and waxes.

Function: These systems capture and convert the volatile compounds produced during pyrolysis into usable liquid products, which are then collected and stored.

Gas Scrubbing And Filtering System

Scrubbers

Function: Gas scrubbers remove impurities and contaminants from the gases produced during pyrolysis. This step is crucial for ensuring the environmental compliance of the process.

Types:

Wet Scrubbers: Use a liquid medium to capture and neutralise harmful gases.

Dry Scrubbers: Use solid adsorbents to remove contaminants from the gas stream.

Filters

Role: Filters remove particulate matter and other solid impurities from the gas stream, ensuring that the gases are clean and safe for further use or emission.

Product Collection And Storage System

Liquid Storage Tanks

Function: These tanks store the liquid products, such as pyrolysis oil and wax, after they have been condensed and separated. Proper storage is essential for maintaining product quality and safety.

Design: Tanks are designed to handle the specific properties of the pyrolysis products, including their chemical reactivity and temperature requirements.

Gas Storage Tanks

Function: Gas storage tanks hold the syngas produced during pyrolysis. This gas could be used for energy generation or as a feedstock for further chemical processing.

Control And Monitoring System

Sensors And Automation

Role: A network of sensors and automated control systems monitor and regulate the various parameters of the pyrolysis process, such as temperature, pressure, and feed rate.

Importance: Effective control systems enhance the efficiency, safety, and reliability of the pyrolysis plant, ensuring consistent product quality and process stability.

Auxiliary Systems

Cooling Towers

Function: Cooling towers support water-cooled condensers by dissipating the heat absorbed by the cooling water, maintaining the efficiency of the condensation process.

Feedstock Preheaters

Role: Preheaters are used to raise the temperature of the plastic feedstock before it enters the reactor, reducing the energy required for pyrolysis and improving process efficiency.

Waste Management System

Char Handling System

Function: This system collects and processes the solid residue (char) produced during pyrolysis. Char could be used as a fuel, a source of carbon black, or in other applications.

Waste Gas Treatment

Role: This system ensures that any remaining gases or by-products are treated to meet environmental regulations before being released or utilised.

Summary

A plastic pyrolysis plant integrates various components, including feedstock preparation systems, feeding systems, reactors, heating systems, condensation systems, gas treatment systems, product collection and storage systems, control and monitoring systems, auxiliary systems, and waste management systems. Each component is essential for ensuring the efficient, safe, and environmentally compliant operation of the plant.

Key Takeaway

Plastic pyrolysis plants include systems for feedstock preparation, feeding, heating, condensation, gas scrubbing, product storage, control, and waste management, ensuring efficient and compliant operations.

Thought Of The Topic

Each component of a pyrolysis plant plays a crucial

role in the process. How could we enhance the synergy between these components

to boost overall efficiency?

Controlling The Quality Of Output In Plastic Pyrolysis

The quality of the output in plastic pyrolysis is influenced by several factors, including the type of plastic feedstock, operational parameters, reactor design, and post-processing techniques. Ensuring high-quality output requires meticulous control over these variables throughout the entire process.

Feedstock Quality And Preparation

Feedstock Composition

Type of Plastics: Different plastics yield different products. For instance, polyolefins like polyethylene and polypropylene primarily produce liquid hydrocarbons, while polystyrene yields styrene monomers. Ensuring a consistent and appropriate mix of plastics could help achieve desired output quality.

Contaminants and Additives: Feedstock contaminated with dirt, metals, or other substances could affect product quality. Pre-treatment steps, such as washing and sorting, are essential to remove contaminants and additives that could degrade the quality of the pyrolysis products.

Operational Parameters

Temperature Control

Optimal Temperature: Precise control of the reactor temperature is crucial. Different plastics have different optimal pyrolysis temperatures. For example, polyethylene and polypropylene typically require temperatures between 300°C and 500°C, while polystyrene may need higher temperatures.

Temperature Uniformity: Maintaining uniform temperature distribution within the reactor ensures consistent thermal degradation, preventing the formation of undesired by-products.

Heating Rate

Controlled Heating: The rate at which the plastic is heated influences the yield and quality of the products. A controlled, steady heating rate promotes uniform breakdown of the plastic and enhances the quality of the liquid and gaseous products.

Residence Time

Optimised Residence Time: The duration that the plastic feedstock remains in the reactor (residence time) affects the extent of thermal degradation. Longer residence times could increase the yield of char, while shorter times favour the production of liquid and gaseous products. Optimising residence time is critical for achieving the desired product mix and quality.

Reactor Design

Type Of Reactor

Batch vs. Continuous Reactors: Continuous reactors, such as rotary kilns and fluidised bed reactors, provide more consistent output quality compared to batch reactors due to their steady-state operation. The choice of reactor influences the control over operational parameters and, consequently, the product quality.

Catalytic Reactors

Catalyst Use: Incorporating catalysts could lower the required reaction temperature and enhance product selectivity. Catalysts like zeolites could improve the quality and yield of liquid hydrocarbons by promoting specific chemical reactions during pyrolysis.

Post-Processing Techniques

Condensation And Fractionation

Efficient Condensation: Condensers cool the pyrolysis vapours to form liquid products. Efficient condensation systems ensure that the maximum amount of condensable vapours is captured, enhancing the yield of liquid products.

Fractional Distillation: Post-condensation, fractional distillation separates the liquid products into different fractions, such as light oils, heavy oils, and waxes. This separation improves the purity and usability of each fraction, ensuring high-quality end products.

Gas Scrubbing And Filtration

Scrubbing Systems: Gas scrubbers remove impurities from the gaseous products, ensuring that the syngas and other volatile products are clean and suitable for further use or emission. Effective scrubbing improves the overall quality of the gaseous output.

Particulate Filters: Filters remove solid particles from the gas stream, preventing contamination of the final products and ensuring compliance with environmental standards.

Quality Monitoring And Control Systems

Real-Time Monitoring

Sensors and Controls: Advanced sensors and control systems monitor key parameters such as temperature, pressure, and gas composition in real-time. Automated feedback loops adjust these parameters to maintain optimal conditions, ensuring consistent output quality.

Data Analytics: Collecting and analysing data from the pyrolysis process helps identify trends and deviations, enabling proactive adjustments and continuous improvement of product quality.

Product Quality Assurance

Laboratory Testing

Sample Analysis: Regular sampling and laboratory analysis of the pyrolysis products are essential for quality assurance. Techniques such as gas chromatography and mass spectrometry assess the composition and purity of the products.

Quality Standards: Establishing and adhering to quality standards for the pyrolysis products ensures that they meet the requirements for their intended applications, whether as fuels, chemical feedstocks, or other uses.

Summary

The quality of the output in plastic pyrolysis is controlled through meticulous management of feedstock preparation, operational parameters, reactor design, post-processing techniques, and quality monitoring systems. Ensuring consistent and high-quality products requires a comprehensive approach that integrates advanced technologies and rigorous quality assurance practices.

Key Takeaway

Controlling the quality of pyrolysis output involves managing feedstock, operational parameters, reactor design, post-processing, and quality monitoring, ensuring high-quality and consistent products.

Thought Of The Topic

Quality control is vital for the success of

pyrolysis products. What innovative methods could we develop to ensure

consistently high-quality outputs?

Main Products Of Plastic Pyrolysis

Plastic pyrolysis converts waste plastics into valuable products through thermal decomposition. The primary products of this process include pyrolysis oil, syngas, and solid residue (char). Each product has its unique characteristics and potential applications.

Pyrolysis Oil

Composition

Hydrocarbons: Pyrolysis oil primarily consists of a complex mixture of hydrocarbons, including alkanes, alkenes, and aromatic compounds. The exact composition depends on the type of plastic feedstock and the pyrolysis conditions.

Applications

Fuel: Pyrolysis oil could be used as a substitute for conventional fuels in industrial furnaces, boilers, and diesel engines after proper refinement. Its calorific value makes it a suitable energy source.

Chemical Feedstock: It could be further processed in petrochemical refineries to produce various chemicals and intermediates used in the manufacture of plastics, solvents, and other products.

Syngas

Composition

Hydrogen and Carbon Monoxide: Syngas is a mixture of hydrogen (H₂), carbon monoxide (CO), and small amounts of methane (CH₄), carbon dioxide (CO₂), and other gases. The proportions of these gases vary based on the pyrolysis conditions and feedstock type.

Applications

Energy Generation: Syngas could be used as a fuel for power generation in gas engines or turbines. Its high energy content makes it an efficient fuel for electricity production.

Chemical Synthesis: It serves as a feedstock for producing synthetic fuels, methanol, ammonia, and other chemicals through processes like Fischer-Tropsch synthesis.

Solid Residue (Char)

Composition

Carbon-Rich Material: Char is primarily composed of carbon, along with inorganic materials such as ash. It is the solid residue left after the volatile components have been driven off during pyrolysis.

Applications

Activated Carbon: Char could be processed into activated carbon, which is used in water purification, air filtration, and industrial processes requiring adsorption.

Fuel: Due to its high carbon content, char could be used as a solid fuel for combustion in industrial processes, contributing to energy recovery.

Soil Amendment: Biochar, a type of char, is used in agriculture to improve soil fertility and sequester carbon, enhancing soil health and reducing greenhouse gas emissions.

Secondary Products And By-Products

Wax